Excavator Undercarriage Components:

The undercarriage of an excavator is a crucial component that supports the entire machine and ensures its stability and mobility on various terrains. Understanding the different parts of the excavator undercarriage can help operators and enthusiasts appreciate the complexity and functionality of these heavy construction machines. Here is an overview of an excavator undercarriage diagram and the functions of its components:

Tracks:

Function: Tracks are made up of interlocking metal links that provide traction and stability to the excavator on rough or uneven surfaces. They enable the machine to move forward, backward, and turn smoothly.

Track Frame:

Function: The track frame is the structure that supports the tracks and connects them to the excavator’s main body. It absorbs shocks and maintains the alignment of the tracks during operation.

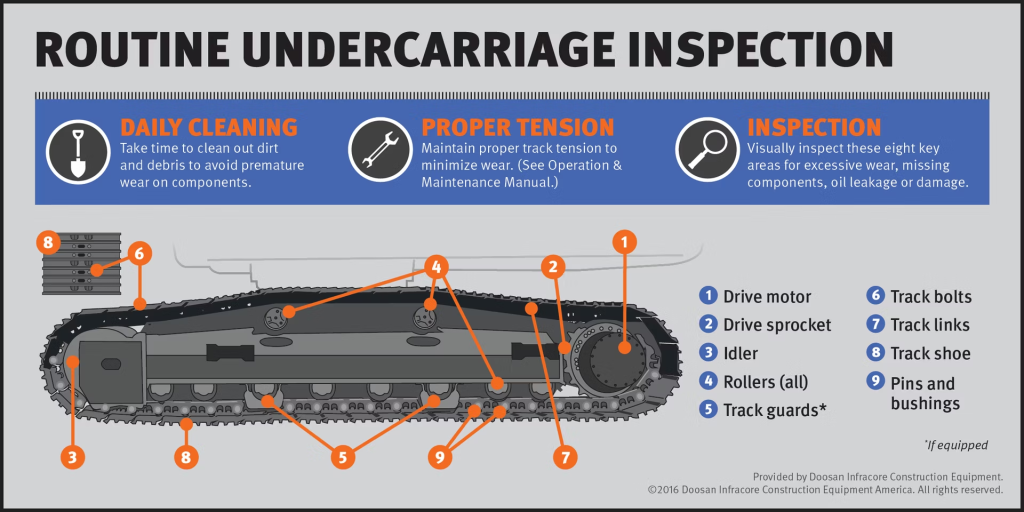

Rollers:

Function: Rollers support the tracks and help distribute the weight of the excavator evenly. They also assist in guiding the tracks and reducing friction during movement.

Idlers:

Function: Idlers are located at the front of the undercarriage and help maintain proper tension in the tracks. They prevent excessive wear on the tracks and ensure smooth operation.

Sprockets:

Function: Sprockets are toothed wheels located at the rear of the undercarriage. They engage with the tracks’ links, driving the movement of the excavator when the tracks rotate.

Importance of Undercarriage Maintenance:

Proper maintenance of the excavator undercarriage is essential to ensure the machine’s longevity and optimal performance. Regular inspections and maintenance tasks include:

Cleaning the undercarriage to remove debris and prevent buildup.

Checking for track tension and adjusting it as needed to avoid premature wear.

Lubricating the rollers, idlers, and sprockets to reduce friction and prolong their lifespan.

Inspecting for wear and tear on components and replacing them promptly to avoid costly repairs.

By understanding the components of the excavator undercarriage and the importance of maintenance, operators can ensure that their machines operate efficiently and safely on construction sites. A well-maintained undercarriage not only enhances the excavator’s performance but also minimizes downtime and repair costs in the long run.