- Previous blog

- Next blog

- Huyett Marketing Department

- 05/20/2021

There is often a need to create space between or limit movement and compression between assembled components. Tubular spacers, arbor spacers, and compression limiters are a reliable solution that satisfy this need. While there are threaded varieties in some of these categories, we will be focusing on those that are unthreaded.

What Are Tubular Spacers?

Tubular spacers are long, hollow, cylindrical spacers with a slot that runs along its length. This provides the spacer some flexibility to expand and contract under loads during installation or use.

How to Choose the Right Tubular Spacer

Tubular spacers are made to metric and inch specifications with heavy or standard wall thicknesses. There are several design considerations when choosing a tubular spacer including size, material, and finish. Spacers are different from compression limiters as there is no or very little gap.

Getting the Right Size

Tubular spacers are made to both inch and metric measurements. Critical dimensions of tubular spacers are length and diameter. Spacer walls come in two thicknesses: standard and heavy duty.

Choosing a Material

Aluminum

is lightweight and provides adequate strength for non‑critical applications. It also has some natural corrosion resistance and does not require coatings or plating for protection against corrosive agents.

is lightweight and provides adequate strength for non‑critical applications. It also has some natural corrosion resistance and does not require coatings or plating for protection against corrosive agents.

Carbon steel

is a popular, durable solution ideal for critical applications. While it does not possess natural corrosion resistance properties like stainless steel, it can be easily coated or plated for enhanced protection against corrosive elements.

is a popular, durable solution ideal for critical applications. While it does not possess natural corrosion resistance properties like stainless steel, it can be easily coated or plated for enhanced protection against corrosive elements.

Common Finishes

Plain finish leaves the parts surface in a raw form. It offers the least amount of protection, however a light oil is often applied to protect the part from atmospheric conditions during storage and shipping.

Zinc platingis common for preventing galvanic corrosion as well as a cosmetically appealing appearance. Zinc plating offers more protection than a plain finish. However, it is still susceptible to corrosion when exposed to harsh chemicals and marine conditions.

ArmorGalv® is a zinc alloy thermal diffusion coating. It features a uniform deposition of coating on all surfaces of the part. It is an ideal coating for marine, automotive, mining, and industrial environments.

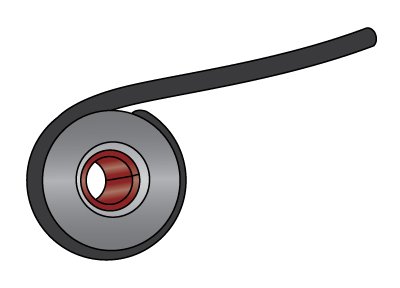

What Are Compression Limiters?

Compression limiters are short, cylindrical tubes that prevent over compression of plastic components. Their primary function is to protect plastic components by supporting compressive loads applied by the torqueing of a screw or bolt at the joint.

Choosing a Compression Limiter

There are multiple considerations to factor when choosing a compression limiter for a given application. This includes limiter type, size, and material.

Which Type of Compression Limiter Should Be Used?

Split seam and knurled compression limiters are the two primary types of limiters, with variations of each type existing.

Split Seam compression limiters use tension to maintain contact with the plastic host component, preventing it from becoming dislodged. As the limiter is installed, it is compressed. After insertion, the limiter returns to its original dimensions providing tension against the inner wall of the host hole.

Knurled compression limiters act differently than split seam. They are one, continuous piece with knurling on the outside face of the limiter. As the compression limiter is installed, the knurls cause swaging of the host material, gripping to the inner wall of the mating hole. The swaged material reduces the risk of spin and pull out in a bolted assembly.

Knowing What Size You Need

When selecting a compression limiter, it is important to know the diameter and height needed in relation to the mating hole. A compression limiter’s weight should be equal to or slightly less than the host component to allow for a small amount of plastic compression when the mating bolt is torqued. The diameter of the compression limiter should also be slightly larger than the mating hole allow for proper host material swaging or expansion of the compression limiter.

Compression limiters are available in metric and inch sizes.

Compression limiters are available in metric and inch sizes.

Choosing Materials

Compression limiters are manufactured in a variety of materials and finishes. Aluminum and brass are common for applications that require light‑weight solutions that are corrosion resistant, whereas carbon steel is ideal for applications subject to higher torqueing forces.

Common Finishes

Brass and aluminum compression limiters are only available with a plain finish. Since they are naturally corrosion resistant and are aesthetically pleasing plating is generally not required. If you require a custom plating solution, give our friendly Sales team a call!

Carbon steel compression limiters are available with zinc clear plating or a plain finish. The zinc plating provides additional corrosion resistance and improved cosmetic appearance over the plain finish.

What is an Arbor Spacer?

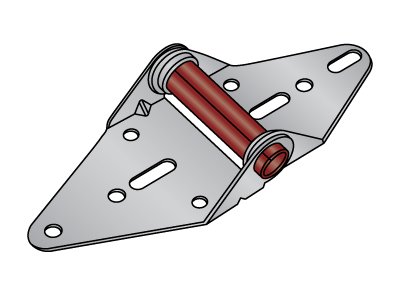

Arbor spacers (keyed spacers or arbor spacer collars) are thick, machined spacers that feature a keyway allowing the spacer to slide over a shaft and machine key during installation. A wide range of tightly toleranced sizes and thicknesses are available for accurate alignment and spacing. Arbor spacers are often installed on slitting saws and milling machines to take up slack.

Choosing an Arbor Spacer

When selecting the appropriate arbor spacer for a given application, size, material, and finish should be considered.

Knowing What Size You Need

Inner diameter, outer diameter, and spacer thickness are primary considerations when determining the size of arbor spacer needed. Key way width and height should also be known to ensure adequate clearance during component assembly.

Common Material and Finish

Arbor spacers are crafted out of durable carbon steel allowing for less wear and high loads during use. Arbor spacers do not have any plating or finish coating thus making them susceptible to corrosive elements when exposed.

Looking For More?

Follow our

blog page for more information on spacers or other products offered by Huyett. If you have questions about a product, visit our

FAQ pages or

give us a call to speak with our friendly experienced Sales Team!

blog page for more information on spacers or other products offered by Huyett. If you have questions about a product, visit our

FAQ pages or

give us a call to speak with our friendly experienced Sales Team!