When it comes to industrial pumping solutions, Seepex pumps stand out as a reliable choice for various applications. Understanding how to operate, maintain, and troubleshoot these pumps is crucial for ensuring optimal performance. This article will provide a comprehensive overview of the Seepex pump manual, covering essential aspects you need to know.

Introduction to Seepex Pumps

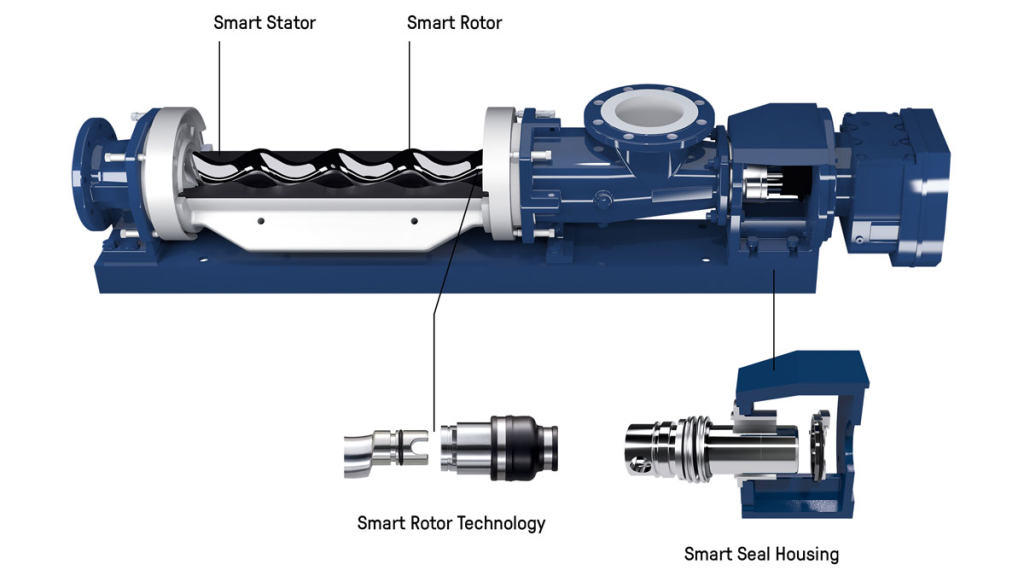

Seepex pumps are progressive cavity pumps designed for the handling of viscous and abrasive fluids. They are widely used in industries such as wastewater treatment, food processing, and chemical manufacturing. The unique design of these pumps allows for smooth and continuous fluid transfer, making them ideal for challenging applications.

Types of Seepex Pumps

Seepex offers a variety of pump models tailored to different operational needs. Some of the most common types include:

- Progressive Cavity Pumps: These are the core of Seepex’s offerings, perfect for transporting thick liquids.

- Rotary Lobe Pumps: Known for their gentle handling of shear-sensitive products, ideal for food and pharmaceutical applications.

- Peristaltic Pumps: Excellent for metering and transferring small volumes of fluid.

Each type is designed with specific features that enhance performance and reliability, and the Seepex pump manual provides detailed information on each model.

Key Features of Seepex Pumps

Understanding the features of Seepex pumps is essential for effective operation. Some notable features include:

- Durable Construction: Built with high-quality materials that withstand harsh conditions and extend the lifespan of the pump.

- Modular Design: Allows for easy maintenance and replacement of parts, reducing downtime significantly.

- Versatility: Capable of handling a wide range of fluids, from thin liquids to highly viscous substances.

These features contribute to the pumps’ efficiency and reliability, making them a preferred choice in various industries.

Operating Your Seepex Pump

The Seepex pump manual provides step-by-step instructions on how to operate the pump effectively. Key operational guidelines include:

- Installation: Proper installation is vital. Ensure that the pump is mounted securely and that all connections are tight to prevent leaks.

- Start-Up Procedures: Follow the specific start-up procedures outlined in the manual to ensure safe and efficient operation. This includes checking fluid levels and ensuring that all components are correctly aligned.

- Adjusting Flow Rates: Depending on the application, you may need to adjust the flow rates. The manual provides detailed instructions on how to make these adjustments safely.

Maintenance Guidelines

Regular maintenance is crucial for the longevity of Seepex pumps. The manual outlines essential maintenance tasks, including:

- Routine Inspections: Regularly check for signs of wear and tear, leaks, or unusual noises. Early detection of issues can prevent more significant problems down the line.

- Cleaning: Ensure the pump is clean to avoid contamination of fluids. The manual provides guidance on safe cleaning methods.

- Lubrication: Proper lubrication of moving parts is essential for smooth operation. The manual specifies the types of lubricants suitable for different pump models.

Troubleshooting Common Issues

Even with regular maintenance, issues may arise. The Seepex pump manual includes a troubleshooting section that addresses common problems, such as:

- Reduced Flow Rate: This could indicate a blockage or wear in the pump components. The manual provides steps to identify and rectify the issue.

- Unusual Noises: Noises can be a sign of mechanical failure. The manual helps diagnose the source of the noise and recommends solutions.

- Overheating: If the pump overheats, it may be due to insufficient lubrication or excessive load. The manual guides you on how to address this problem.

Safety Precautions

Safety is paramount when operating any industrial equipment. The Seepex pump manual emphasizes the importance of following safety guidelines, including:

- Personal Protective Equipment (PPE): Always wear appropriate PPE to protect against spills and potential hazards.

- Emergency Procedures: Familiarize yourself with emergency shutdown procedures and ensure all operators are trained on these protocols.

Conclusion

The Seepex pump manual is an invaluable resource for anyone working with Seepex pumping solutions. By understanding the types of pumps available, their features, and how to operate and maintain them, you can ensure optimal performance and longevity. Regular maintenance and adherence to safety precautions are essential for avoiding issues and maximizing efficiency. For any specific questions or advanced troubleshooting, always refer back to the manual or consult a qualified technician. Embracing the guidance provided in the Seepex pump manual will not only enhance your operational knowledge but also contribute to the overall success of your pumping applications.