Pumps are essential components in various industries, from wastewater treatment to food processing. However, like any mechanical device, they can encounter issues that disrupt operations. Understanding these common problems and how Seepex distributors can assist in resolving them is crucial for maintaining efficiency.

Common Issues with Pumps

- Cavitation

- Cavitation occurs when vapor bubbles form in the fluid being pumped and collapse, causing damage to the pump. This can lead to reduced performance and increased wear.

- Seal Failures

- Over time, seals can degrade due to wear, heat, or chemical exposure. This leads to leaks, which can create safety hazards and reduce operational efficiency.

- Blockages

- Pumps can be susceptible to blockages from solid particles or debris in the fluid. These obstructions can cause overheating and lead to pump failure if not addressed promptly.

- Vibration Issues

- Excessive vibration can indicate misalignment or imbalance in the pump or motor. This can lead to premature wear and tear, impacting the longevity of the equipment.

- Inadequate Flow Rates

- A drop in flow rate can signify issues such as wear in the impeller or blockage in the piping system. This can disrupt processes that rely on consistent flow.

How Seepex Distributors Can Help

Seepex distributors play an essential role in addressing and preventing these common pump problems. Their expertise and knowledge make them valuable partners for businesses relying on pump systems.

Expert Consultation

Seepex distributors offer expert consultation to help identify the root causes of pump issues. By assessing the specific needs of a facility, they can recommend the best solutions tailored to unique operational requirements.

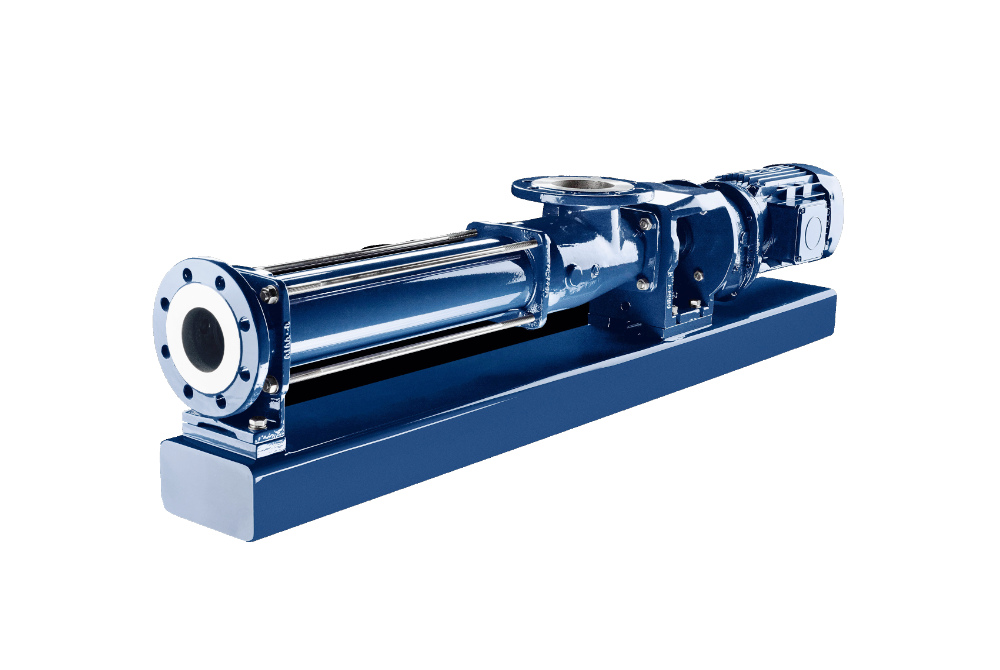

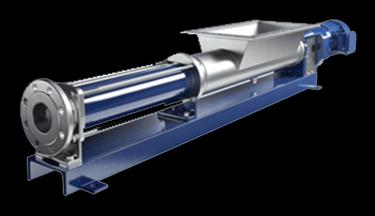

High-Quality Products

Distributors of Seepex are known for providing high-quality, reliable products. They offer a range of pumps and spare parts that meet industry standards, ensuring durability and efficiency.

Regular Maintenance Services

Preventive maintenance is crucial for extending the lifespan of pumps. Seepex distributors provide regular maintenance services, helping to identify potential issues before they escalate into costly problems.

Training and Support

Seepex distributors often provide training for staff on proper pump operation and maintenance. This empowers employees to identify issues early and reduces the risk of operational disruptions.

Custom Solutions

Every operation is unique, and Seepex distributors understand this. They offer customized solutions to meet specific needs, whether it’s a unique pump configuration or tailored maintenance schedules.

Conclusion

Pumps are vital for many industrial processes, but they can encounter a range of common problems. Understanding these issues and knowing how Seepex distributors can help is essential for maintaining efficient operations. With expert consultation, high-quality products, and ongoing support, Seepex distributors are equipped to ensure that your pump systems run smoothly and effectively. By partnering with them, businesses can minimize downtime and enhance productivity, making them an invaluable resource in the industry.