Choosing the right cavity pump manufacturer is crucial for ensuring that your industrial operations run smoothly and efficiently. Cavity pumps are widely used in various applications, including food processing, chemicals, and wastewater management. This guide will help you navigate the key factors to consider when selecting a manufacturer.

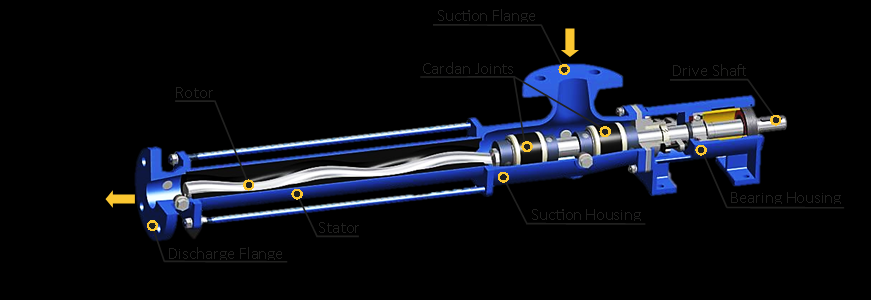

Understanding Cavity Pumps

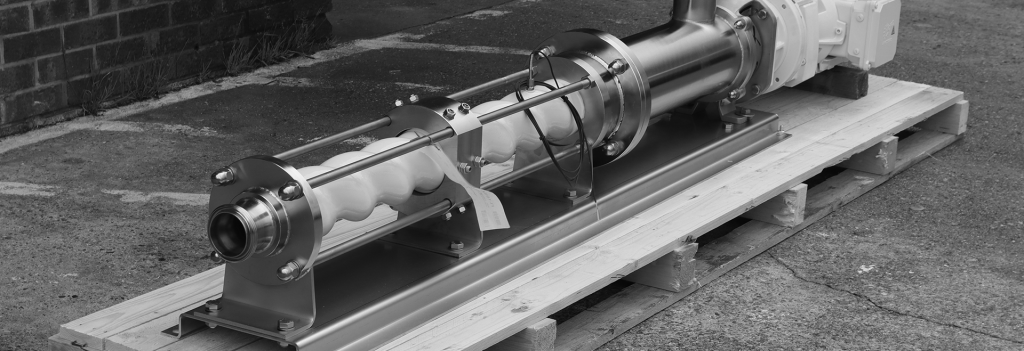

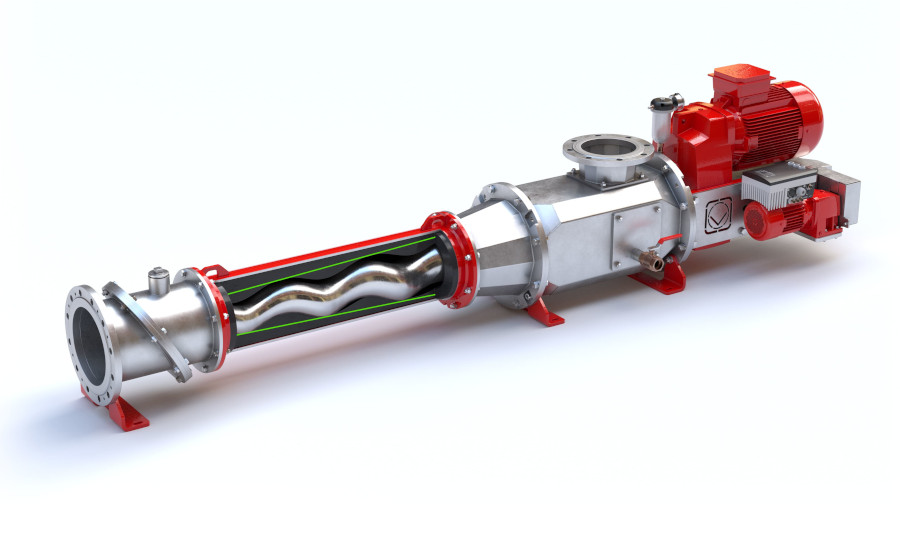

Cavity pumps, also known as progressing cavity pumps, utilize a helical rotor to create cavities that move fluids through the pump. They are particularly effective for handling viscous and shear-sensitive materials. Understanding the unique features and benefits of cavity pumps will help you identify the right manufacturer for your needs.

Key Features of Cavity Pumps

- Versatility: Capable of handling a wide range of fluids, from thin liquids to thick slurries.

- Low Shear: Ideal for sensitive materials that require minimal agitation.

- Self-Priming: Can handle air entrainment, making them suitable for various applications.

- Consistent Flow: Provides a steady and uniform flow rate, which is essential in many industrial processes.

Factors to Consider When Choosing a Manufacturer

Selecting the right cavity pump manufacturer involves several considerations. Here are the most important factors to keep in mind:

1. Experience and Reputation

A manufacturer with a solid track record and industry experience is more likely to produce reliable and high-quality pumps. Look for manufacturers who have been in business for several years and have a reputation for excellence.

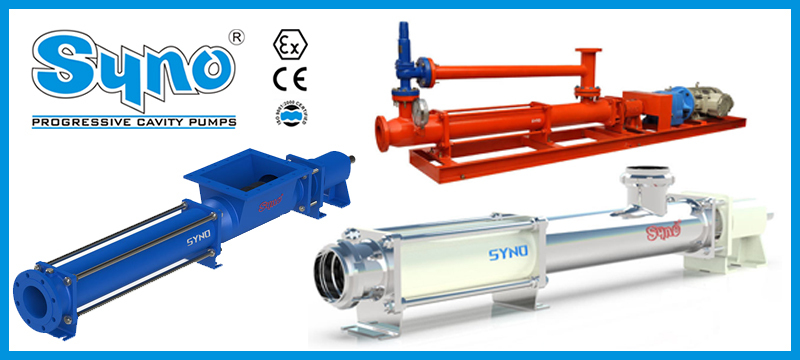

2. Product Range

Evaluate the manufacturer’s product range to ensure they offer a variety of cavity pumps that meet your specific requirements. A diverse product line can provide you with options for customization and upgrades.

3. Quality Assurance

Quality is paramount in the manufacturing process. Inquire about the manufacturer’s quality control processes and certifications. A manufacturer that adheres to international standards demonstrates a commitment to quality.

4. Technical Support

Technical support is vital for the successful operation of cavity pumps. Ensure the manufacturer provides comprehensive support, including installation guidance, maintenance services, and troubleshooting assistance.

5. Customization Options

Every application is unique, and sometimes standard pumps may not fit your needs perfectly. Look for manufacturers that offer customization options to tailor pumps to your specific application requirements.

6. Customer Reviews and Testimonials

Research customer reviews and testimonials to gain insight into the experiences of other users. Positive feedback can indicate reliability and satisfaction with the manufacturer’s products and services.

7. Pricing and Value

While cost should not be the sole factor in your decision, it is essential to consider pricing in relation to the quality and features offered. Look for manufacturers that provide good value for money without compromising on quality.

Making the Final Decision

Once you have evaluated potential manufacturers based on the factors listed above, it’s time to make your decision. Here are some steps to follow:

1. Request Proposals

Contact shortlisted manufacturers to request proposals. This will give you an opportunity to compare specifications, features, and pricing.

2. Schedule Visits

If possible, schedule visits to the manufacturers’ facilities. This allows you to see their operations firsthand and assess their production capabilities and quality control processes.

3. Ask Questions

Prepare a list of questions to ask during your interactions with manufacturers. Inquire about their experience, product warranties, lead times, and after-sales support.

4. Review Contracts Carefully

Before finalizing your decision, carefully review any contracts or agreements. Ensure that all terms are clear, including delivery schedules, warranty provisions, and service agreements.

Conclusion

Choosing the right cavity pump manufacturer is a critical decision that can significantly impact your operations. By considering factors such as experience, product range, quality assurance, and customer support, you can make an informed choice. Take your time to evaluate your options, and remember that investing in a reputable manufacturer will pay off in the long run with reliable performance and reduced operational issues.